Stage 1

The most important part of any furniture is the raw material. We use FEQ and FSC Teak, FSC Oak, FSC and PEFC Iroko also FSC British Sweet chestnut.

The certification is your guarantee of traceability – virtually from seedling to your garden. WHY? simply because our natural resources are under constant threat, and whilst we do NOT use trees from the worlds rain forests they are being decimated daily.

Secondly is harvesting, sawing, drying, shipping and storage once in our care.

These elements are covered during the process detailed below.

Stage 2

Trees are carefully selected for, and to create the most usable sawn boards for furniture creation. Back along it was traditional for teak trees to be ringed to prevent sap from rising, stopping the growing process before felling. Modern methods, the demand for timber and the speed at which the world now turns makes the traditional methods virtually redundant. Once felled trees are carried to the sawmills.

Stage 3

The sawmills now create the boards you can see here, these are then shipped to either air drying yards, a long and costly process meaning that is can take up to 7 years to bring the moisture content down to useable levels. The more widely used process is kiln drying. This entails the timbers of similar dimensions being placed into large ovens, with spacing sticks placed between every layer and warm air forced through to effectively dry in a much quicker time. Obviously the thinner the boards the quicker the process.

Stage 4

We obtain our timbers from various sources, direct from the countries of origin, reputable merchants or indeed in the case of sweet chestnut straight from the forest in Herefordshire.

Upon arrival at our works again the boards are ‘sticked’ graded and placed in to size order making selection easier. As mentioned we carry large stocks of teak, oak, Iroko and a much smaller selection of sweet chestnut.

Stage 5

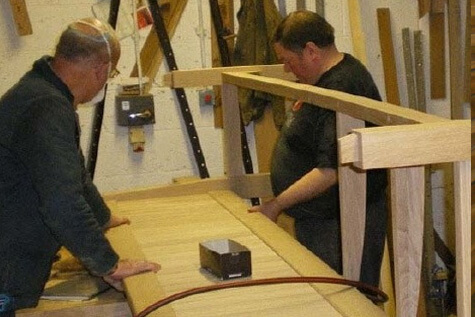

Once we receive your call, email or indeed a visit we will confirm your requirements to ensure we have everything correct. then a job card is raised this job number is your reference, along with obviously your name. Your order and job is passed to our production team then when production space is available a dedicated and fully qualified master craftsman is given you furniture to create. Normally all your order will be created by a single person, this gives our carpenters real pride in the job and an affinity with your needs. This results in a much closer bond between us.

Stage 6

During creation every component of your order is quality checked and each assembly stage again gets a careful inspection. Once your furniture is completed, checked again and even then finally rechecked again upon loading. We deliver every piece of furniture using our own transport and staff. Your furniture is carefully wrapped or blanketed, tied carefully with soft webbing and despatched with a delivery date and approximate time of arrival pre-agreed.

The result is delivered perfection. You only purchase top quality garden furniture once – make it the very best.

Stage 1

The most important part of any furniture is the raw material. We use FEQ and FSC Teak, FSC Oak, FSC and PEFC Iroko also FSC British Sweet chestnut.

The certification is your guarantee of traceability – virtually from seedling to your garden. WHY? simply because our natural resources are under constant threat, and whilst we do NOT use trees from the worlds rain forests they are being decimated daily.

Secondly is harvesting, sawing, drying, shipping and storage once in our care.

These elements are covered during the process detailed below.

Stage 2

Trees are carefully selected for, and to create the most usable sawn boards for furniture creation. Back along it was traditional for teak trees to be ringed to prevent sap from rising, stopping the growing process before felling. Modern methods, the demand for timber and the speed at which the world now turns makes the traditional methods virtually redundant. Once felled trees are carried to the sawmills.

Stage 3

The sawmills now create the boards you can see here, these are then shipped to either air drying yards, a long and costly process meaning that is can take up to 7 years to bring the moisture content down to useable levels. The more widely used process is kiln drying. This entails the timbers of similar dimensions being placed into large ovens, with spacing sticks placed between every layer and warm air forced through to effectively dry in a much quicker time. Obviously the thinner the boards the quicker the process.

Stage 4

We obtain our timbers from various sources, direct from the countries of origin, reputable merchants or indeed in the case of sweet chestnut straight from the forest in Herefordshire.

Upon arrival at our works again the boards are ‘sticked’ graded and placed in to size order making selection easier. As mentioned we carry large stocks of teak, oak, Iroko and a much smaller selection of sweet chestnut.

Stage 5

Once we receive your call, email or indeed a visit we will confirm your requirements to ensure we have everything correct. then a job card is raised this job number is your reference, along with obviously your name. Your order and job is passed to our production team then when production space is available a dedicated and fully qualified master craftsman is given your furniture to create. Normally all your order will be created by a single person, this gives our carpenters real pride in the job and an affinity with your needs. This results in a much closer bond between us.

Stage 6

During creation every component of your order is quality checked and each assembly stage again gets a careful inspection. Once your furniture is completed, checked again and even then finally rechecked again upon loading. We deliver every piece of furniture using our own transport and staff. Your furniture is carefully wrapped or blanketed, tied carefully with soft webbing and despatched with a delivery date and approximate time of arrival pre-agreed.

The result is delivered perfection. You only purchase top quality garden furniture once – make it the very best.

The drying process is an important part of preparing wood for use in outdoor furniture. Although it is impossible to completely eliminate dimensional shifts in a piece of wood, by removing any excess moisture, such shifts are minimised, so changes in the weather are less likely to result in the wood warping or splitting.

PLEASE NOTE – ALL HARDWOODS TURN SILVERY GREY WHEN OUTDOORS, THIS IS A TOTALLY NATURAL PROCESS

Teak

TEAK is exceptionally stable with the minimum of movement and widely accepted as the very best timber for garden furniture.

Iroko

IROKO again is a very heavy and durable hardwood, but not as stable as teak. We use Iroko for all our very heavy picnic tables and larger benches when requested. Can occasionally split similar to oak.

Oak

OAK is a fantastic timber for outdoor and indoor furniture but can be sometimes unstable especially in its early life – sometimes it never moves, on others it can warp and split this is totally natural and does not effect the structural strength only the aesthetics. You have only to look at old oak framed barns and houses to see the wonderful shapes the beams have formed but still standing strong and proud.

Sweet Chestnut

SWEET CHESTNUT similar in appearance to oak but much lighter in weight, is prone as is oak to moving and splitting before it settles in to its new surroundings.